Exterior doors vs. thermal insulation – how to choose the right one?

Back to guideExterior doors vs. thermal insulation – how to choose the right one?

Choosing a front door is a decision dictated by both functionality and aesthetics. Reviewing the offers and considering the solution that suits us, we must pay close attention to how their thermal transmittance parameters are. This will be a factor that directly affects heating bills and comfortable temperature in the entrance hall or vestibule. Let’s take a closer look at this issue to find out what thermal insulation for doors is worthy of attention?

What are the best insulation materials in exterior doors?

Styrofoam is an inexpensive, proven and common solution, used for the purpose of ensuring the warmth of the door performs well, although a certain limitation here is the thickness of the insulation itself, necessary to achieve good performance. The compact structure, low thermal conductivity, durability of shape, resistance to temperature fluctuations and the harmful effects of moisture, and thus the development of mold or mildew make polystyrene a great filling material for entrance doors.

Mineral wool is non-combustible, flexible and resilient, unfortunately, in order to provide the expected degree of insulation its layer must be really large, which negatively affects the weight of the door leaf and its thickness, nevertheless it is a very good material for use in fire doors, cutting off the passage of flames.

A certain novelty in the field of door thermal insulation is aerogel – a thin, flexible and very lightweight material that has already proven its usefulness in the construction industry, including for insulating pipelines and water tanks, as well as the inner chambers of window profiles. It offers high pressure and bending strength, class A fire resistance, is not affected by moisture and prevents the growth of mold or the multiplication of bacteria. A major drawback in the popularization of this filling is, unfortunately, its still relatively high price.

Does door thickness affect thermal insulation?

The thickness of the door leaf in itself does not determine good thermal performance, as this is influenced by the infill techniques used. The aforementioned insulating materials have different properties at the same thickness, so it is the raw material used in the production of the door and the thermal insulating filler that determine the effectiveness of the whole solution. So basically, the thickness of the door is determined by the method of its thermal insulation, while if the leaf is not tightly filled because the manufacturer saved on the material, the effect will be hardly satisfactory even with a solid-looking thick door.

How to test the thermal insulation of doors before buying?

From the point of view of efficiency, it is important to choose multilayer doors from reliable manufacturers and pay attention to the parameters specified in the product sheet – the thickness of the sheet and the filling material, as well as the U-value, which determines the thermal transmittance. The lower, the better – thermal insulation with a value below the minimum standard of 1.3 W/m2K, will be a valuable asset, while in energy-efficient passive construction this index will oscillate within 0.7-0.8 W/(W/m2K ). The thermal insulation of the front door is something that manufacturers are eager to boast about, presenting it as an important advantage of their product, fitting for construction oriented towards minimizing heat and energy losses. That’s why this parameter is usually prominently displayed, as long as the door leaf has something better to offer than the legally required minimum.

Thermal insulation testing of doors can also be found on videos that show the behavior of a door leaf when the temperature changes. This is also an interesting study, because it allows you to find out, by the way, whether the model we have chosen and its filling will protect against excessive heating of the door in the summer, especially if it is exposed to the sunny side. In air-conditioned rooms this is of considerable importance – after all, in hot weather we do not need a solar-powered heater of considerable size.

Should exterior doors have additional seals?

For thermal doors, gaskets are selected that are resistant to the passage of time and adverse weather conditions, and have great flexibility and ductility to return to their original shape. What kind of gaskets for thermal doors are used? First of all, they should be perfectly matched with the door frame and door leaf to form an integral whole, silicone rubber or TPE elastomers are most often used for their manufacture.

Modern doors for passive houses are installed with additional insulation tapes covering the door-wall junction, which regulates the proper flow of water vapor and prevents it from accumulating in the thermal insulation layer. In order to achieve better gasket performance, solutions are also being introduced with a design consisting of flexible polyurethane foam as its filling, coated on the outside with a thin polyethylene film and embedded in a polypropylene mandrel. This provides excellent shape memory, low stretch and very good thermal conductivity of the seal.

Adding additional seals on your own will make sense when you sense pronounced blowouts, caused, for example, by the carelessness of the door assembly or the wear of factory seals. Brush seals, attached from below to the door leaf in the form of self-adhesive bristle tape, are an interesting option. They seal, reduce noise levels and additionally protect against moisture and dust.

What other functions can support the thermal insulation of the door?

Of course, choosing a door is not the end of the story, as it still needs to be properly installed and adjusted precisely, according to the art, to avoid blowouts through poor fit or careless installation. When inclined to choose an exterior door with glazing, also pay attention to whether the manufacturer offers the so-called warm frame and triple-glazed package, filled with noble gas.

Door thresholds with thermal interlocks, made of special materials that do not conduct heat and reduce condensation, are increasingly common. Such “warm thresholds” also minimize the phenomenon of seals freezing and their destruction in severe frosts, while reducing the risk of mold or fungus growth on the floor near the entrance to the house.

See also

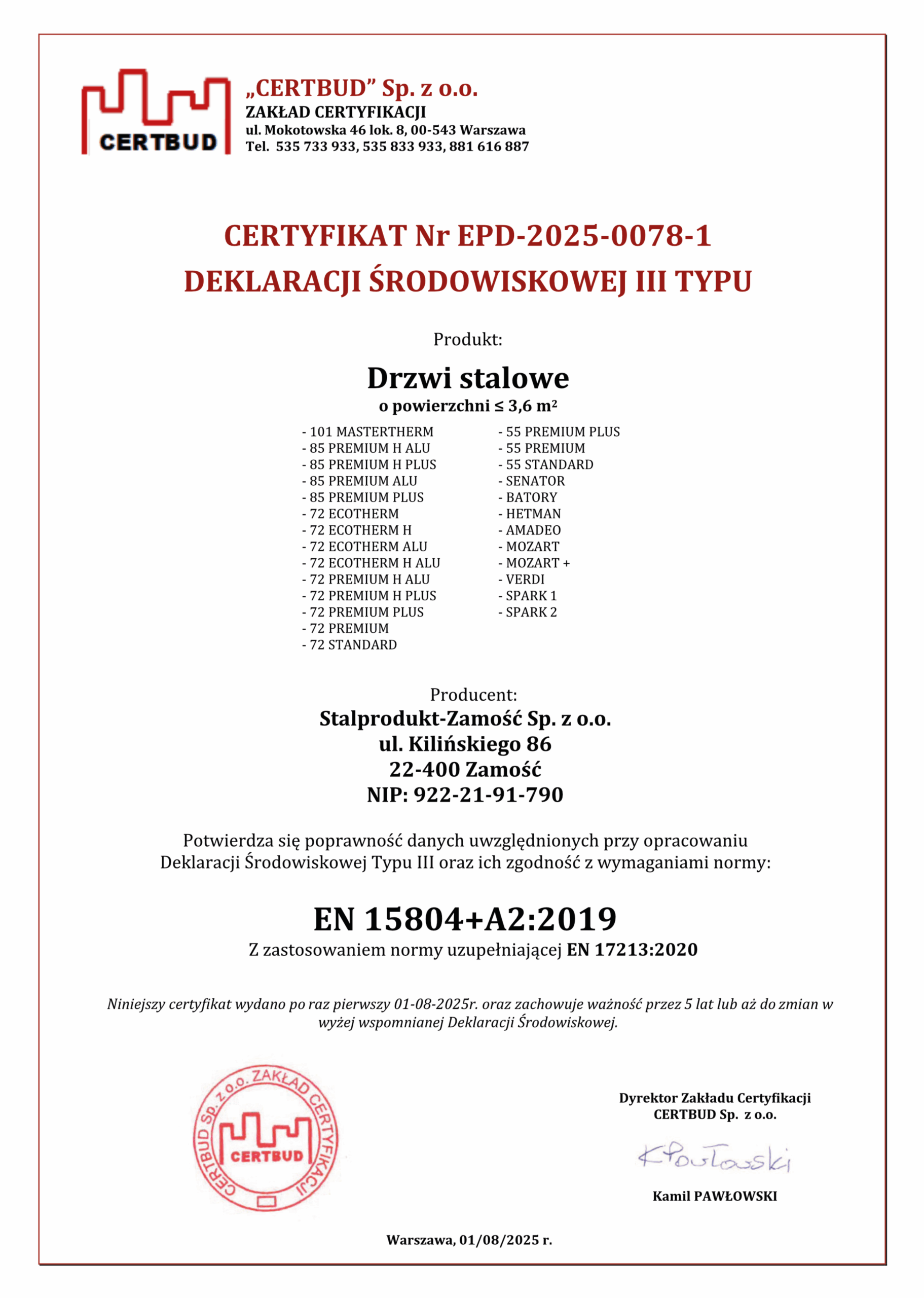

EPD – the certificate of the future in the industry

At Stalprodukt-Zamość Sp. z o.o., we believe that responsibility for a product does not end with its functionality,…Read more

What color exterior door to choose for your home? Practical tips

What color exterior door to choose for your home? Practical tips Choosing an exterior door is a decision…Read more

When to install exterior doors in a new home, and when to install interior doors?

When to install exterior doors in a new home, and when to install interior doors? The construction of…Read more